Backstage is my beat: Barebones. Unbuttoned. A tad askew. Lighted only for tasks. Focus with chuckles, where the magic gestates.

Backstage is my beat: Barebones. Unbuttoned. A tad askew. Lighted only for tasks. Focus with chuckles, where the magic gestates.

Early in my pottery-marketing career (at a student sale) someone kindly schooled me in another form of transacting: “Artists don’t buy from each other, they trade!” she chided and grinned. And so we traded: hers for mine, mine for hers. It was right for all the right reasons.

I have now traded bunches of times. Some were as sweet and simple as that first, others not so much. I’m not often the one to suggest it, yet I usually don’t say no when a swap is proffered. That is mostly because I haven’t found a good rationale to refuse: a trade is always interesting, even if it goes awry. And every time it gets out of alignment (but never because of me! 😉 ) I get better at avoiding the pitfalls of forgetful, stingy, unskilled, or unrealistic traders, of which I have sadly met a few.

I recently wrote about this piece of mine – the Vitri-Oil Tea Can – which arrived for an important exhibit with the handle broken in five places. If you want the full story of the original heartbreak, you can read about that and then come back here for a recitation of events and the exciting conclusion in annotated timeline form.

UPDATE: This sad tale of ceramic breakage with a happily-repaired ending was first published January 21, 2012. I DID make the hangtags I refer to within, but I wound up keeping this sentimental piece. It deserved a good home: mine!

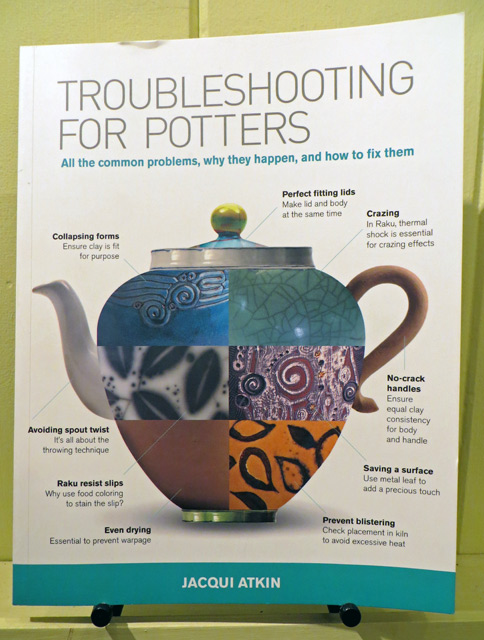

If you’re involved in clay, you certainly know you’re involved with problems. Some of them you asked for just by stepping into your creativity. Some are borne of being a beginner in the medium and you learn by doing, making plenty of mistakes, and doing again. These are good problems to have! Dig in and have a blast.

Then there are the un-asked-for and un-fun problems. The ones that repeatedly spoil things and you can’t seem to shake. Whyyyyyy? The possible solutions start to be more specific and scarcer. Maybe you find yourself scrambling to learn the applied chemistry, math and physics you thought you never needed. Or you’re seriously delving into a study of cracks and explosions, dunting and shivering. Advice differs. Opinions vary widely and sometimes there are just too many of them. And now it seems you need help with triaging both the problems and the possible remedies.

You need an intelligent and reliable reference book.

POST UPDATE: This post was originally published on September 3, 2009. I am repeating it because it is just one of those ideas which need to circle round every five years or so and it’s a bit overdue. I still have all of the caddies I made seven years ago, going strong and serviceable. Whenever I have one with me in a class or workshop, folks want to know more. I wound up taking copies of the instructions to give the serious inquirers. I did make an industrial-sized caddy and it’s great for holding bigger stuff: rulers, dowels, long-handled anythings. Hope you enjoy yours.

Original Post:

If you’re as much of a tool geek in your art as I am in mine, you most likely need a Soup Can Tool Caddy, so this post is for you and you and YOU! (And for word-wrangler Cynthia Morris who has admitted she just likes to say, “Soup Can Tool Caddy.”)

I wish I could claim I dreamed up this drop-dead obvious assemblage of simple, cheap and recycled things, but I can’t. All I know is the day I saw it in the Suggestions From Readers column in the January, 2005 issue of Ceramics Monthly magazine, I knew I was gonna make it.

The original parts list and instructions came from Michell Follett of Oakland, CA. There’s definitely no ‘e’ at the end of Michell, and I found her once on Facebook: She’s sitting at her wheel, gesturing with a collapsed pot. Ya gotta love a potter with a funnybone!

I can’t find a link to the original blurb, but it’s short, so I will re-type the heart of it.

Take it away, Michell:

Parts List

six 15oz. aluminum cans, labels removed

six 3/4 inch screws

one 1 1/2x3x9 inch piece of wood [My Note: Scrap 2x4s (techically known astubafors)…I have used shorter, just make sure it will span the row of three, mid-can to mid-can.] one 6 1/2 inch zinc-plated pull (handle) [My Note: Shorter is OK here too] one can of Rustoleum spray paint.

Easy Instructions

Spray the cans (inside and out) and the wood with Rustoleum. Attach three cans to each long side of the wood (it helps to pre-drill holes in wood and cans.) Insert screws at an angle. Attach pull to top of wood.

Long-time Maker/User Comments from Me

I had the most difficulty getting it level, cuz I’m not that handy, really, so just spend a tiny bit of extra time lining things up before attaching.

If you plan to store anything wet, it wouldn’t hurt to punch a small hole in the bottom of each can for drainage.

If you’re at all concerned, of course you can re-spray if the paint gets worn.

So, in Full Disclosure, here’s how far it has gone for me:

And, Necessity being the Mother it is, this is my most recent addition to the fold, made from larger around, but shorter Trader Joe’s Premium Chunk White Chicken cans:

Got any fun-sounding titles for the new one? L’il Chunky, or The Chicken Caddy?

For that matter, got any other interpretations in size/function? What about one from industrial, food service, Costco-sized containers?

I know for sure that if you make just one, the tools you have will be more easily findable and portable. And the magical-thinking part of me intuits that making one extra will attract all the other tools you want. Start rinsing out those cans!

–Liz Crain, who likes a simple thing done well.