You might tend to think a ceramic artist pulls her work hot out of the kiln, lets it cool and plops it on the sales table, done. And there ARE tales of potters doing just that at their kiln openings. Ah, were it that simple for me! What follows are a few illustrated reasons why, in my world, there’s a slight cha cha interlude from kiln to market.

The particular firing illustrated here was the most recent I unloaded. I photographed the steps I usually take with my pieces. From waiting for the right time to unload to putting a sticker on the bottom, there are lots of hoops.

The Kiln – with Thumb Genie and Humorous Caution Sticker. I double-crossed my fingers with this giant and varied load. Firing my biggest kiln, Tsunami, always feels like I have too many eggs in one basket. To add to the apprehension, the last couple of firings revealed some serious cracking issues which might reappear. Still, there is no way out but through, so I loaded, left it on low to preheat the work slowly, closed the lid on a slow firing cycle, thinking I would just sneak up on it all.

Next morning, I am almost happy when the kiln is too hot to open yet. Saves me the knowledge of certain success or certain failure and lets me stew longer. Here’s the pyrometer saying it’s WAY too hot to even peek. Ahhh.

At under 300 degrees, it’s only sort of OK to peek briefly because it shocks and cracks the glazes. Lower than 200 degrees, I can prop the lid and help it cool faster. My first brave and nervous glimpse says all is well from the long view. I cannot stress how much of a relief this is after a night of cracked-up and distressing dreams. I wear my well-used Ove Gloves when I unload just in case I hit a hot bottom or something.

After the long view (nothing blown up or majorly cracked apart at first sight) there is the not-s0-small matter of whether the lids release. I build my lids with a bit of ease (aka “shuffle”) around the spouts/flanges, but everything gets so soft in the heatwork of the kiln, it’s not uncommon for random spots to stick together, especially if gravity and proximity are involved. Before firing I paint on generous coats of wax-with-added-alumina and even so, stick happens. A completely stuck-on lid means a lost piece, so I’ve learned to breathe deeply and tap a wooden stick with gentle authority on a stuck lid. Too much force and something breaks off. Not enough, and the glassy connector-spots don’t separate. Always nerve-wracking. This was the only stuck on lid in the load and gave up after 20 or so gingerly assertive taps.

I inspect each piece as I take it out of the kiln. Top, bottom, sides, handles, spouts, seams, attachments. Anything come undone? Anything displaying movement or warping? I also test each piece for water-tightness. I put a bit of water in each one and let it sit on a paper towel for a few minutes, which is what you see here. It’s pretty clear when I’ve got a leaker and sometimes it is from the least visible places. After the close inspectiion and the water testing, I can let myself start to believe I have a viable piece.

Next comes sanding. I don’t generally glaze my exteriors, but I’ve learned they LOVE being sanded. Just a quick pass with a fine grit and we have a silky smooth surface to touch. If more is needed, there is the alumina stick or the piece of broken silicon carbide kiln shelf to knock chunks off. Every piece gets lightly sanded at the minimum. Every now and then there is a sharp edge to amend.

Let’s measure! Height x Width x Depth….Cannot do this before the final high temp firing because things shrink just that much more. That info gets entered on the individual studio log sheet I keep detailing the forming and decorating.

Here’s a studio log sheet for one piece: Title/Description, Inventory/Category Number, Sketch, Clay Body, Underpainting, Liner Glaze, Surface Design, Firing Notes, Refiring Notes, Dimensions, Price, Show Record, Purchase Notes. This page has evolved over the years and I need to make some updates, but the idea has served me well since my student Glaze Logs. I keep several binders of these pages, filed for the different types of work I do. Some similar groups have spread sheets instead of individual pages. I also have binders for Sold or otherwise GONE work. It’s a LOT of maintenance and worth it.

In the past year, I have added this digital way to keep track of my work. Artwork Archive is a great adjunct to my written studio notes. I don’t add every single piece, just the ones that have gone out into the world to galleries or exhibits. After the completely tedious data entry part, all I have to do is click and I can see what work is where. Helps me stay sane and feel competent.

Every piece gets photographed. This actually has to happen before the digital Artwork Archive can be completed, but the photo set-up, the shots, the editing, resizing and organizing will go on with or without that. I have several sizes of light tents, backdrops and lights, but I tend to use the simplest version of everything. Digital cameras and all are so good, I just don’t stress over the photo documentation like I did say ten years ago.

An inventory sticker goes on the bottom of each piece and the whole scene is connected. I will add a separate price sticker sometime in the future, which means I will return to the Studio Log and Artwork Archive. Before pricing, I usually set out all my work and physically move it around trying to understand goodness, value, artistic merit, improved design, market rates and past sales in a holistic way before I price anything. It’s probably the hardest part.

The upshot of this whole process is I intimately know each of my pieces, start to beyond the finish firing before they fly away into the hands and hearts of my collectors.

-Liz Crain, who, if she had been told ahead of time about the After the Firing ministrations needed, might have not gotten so deep into this clay thing. But then again, it’s pretty much a moot point now, right?

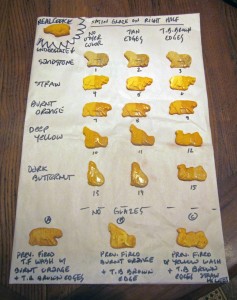

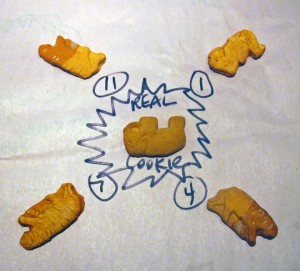

After a few more trial runs and notes, the Final Four Finishes (ignoring the clear glaze on some of them) sit alongside a real cookie and ask for comparison. The crowd-sourcing group preferred #4 without the glaze, and so did I, so that finish was the emphasis in the next round:

After a few more trial runs and notes, the Final Four Finishes (ignoring the clear glaze on some of them) sit alongside a real cookie and ask for comparison. The crowd-sourcing group preferred #4 without the glaze, and so did I, so that finish was the emphasis in the next round: The Final Four Finishes Favorite with an added toasty edging. Could anyone guess the real ones from a random grouping of clay? In this shot the real ones are turned over, but most could not distinguish among the lot beforehand. The closest guesser noticed the excess material at the mold’s edge, not the applied colors. The job ahead was clear: make neat moldings and color them well.

The Final Four Finishes Favorite with an added toasty edging. Could anyone guess the real ones from a random grouping of clay? In this shot the real ones are turned over, but most could not distinguish among the lot beforehand. The closest guesser noticed the excess material at the mold’s edge, not the applied colors. The job ahead was clear: make neat moldings and color them well.

The task at hand: to color and glaze fire the collection. The sheer volume is daunting. Time to put tailbone on the stool and just get it done.

The task at hand: to color and glaze fire the collection. The sheer volume is daunting. Time to put tailbone on the stool and just get it done.